Hand blast cabinets

The PRO-impact line consists of our dry blasting cabinets. Depending on your application, a vacuum or pressure projection system, equipped with an abrasive recovery and filtration system may be suggested.

Different types of industrial installations work according to the dry blasting technology. Depending on your application, a hand blast cabinet, a blasting hall with associated blasting equipment, a mobile and compact system (including the MCS² or MVS²) or even microblasting equipment may be the best solution. Both manual and automated versions are possible. We help you determining the installation and configuration.

You are also welcome for all related spare parts, consumables and personal protective equipment. Our warehouse has a large stock of abrasives, cleaners, additives & process fluids.

The PRO-impact line consists of our dry blasting cabinets. Depending on your application, a vacuum or pressure projection system, equipped with an abrasive recovery and filtration system may be suggested.

In addition to our standard automated blasting installations, we develop customized robotic installations. Projects are delivered turnkey.

We set up your blasting hall and provide the associated equipment such as the abrasive transport system, the abrasive recuperation system and the ventilation system for effective dust removal.

The JET-impact line consists of industrial blast pots: CE-approved, available from 20 L to 300 L and smooth discharge of the abrasives guaranteed.

The VACU-impact line consists of mobile dust-free blasting systems in closed circuit: compact blasting systems for sporadic use and industrial systems for full-time use.

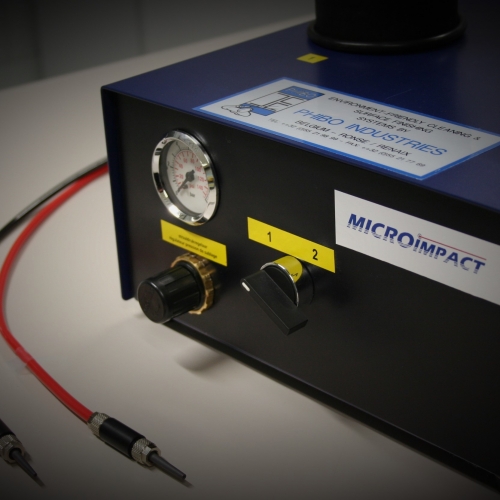

The MICRO-impact line consists of micro-blasting equipment, suitable for blasting small parts with extreme accuracy.