Are you looking for a qualitative 'dust-free' blasting system? The MVS² is a compact, mobile and dust-free blasting system. It is characterized by its simplicity and user-friendliness. The blasting gun with built-in 'blasting chamber' is placed against the surface to be treated. The abrasive is first projected in this blasting chamber and then immediately suctioned off and recycled. Thanks to the integrated abrasive recuperation and filtration system, the abrasive consumption is considerably lower than with standard blasting and stripping systems. The careful development and choice of materials guarantee a maximum cleaning power at the best price-quality ratio.

The MVS² consists of 3 components. The MVS² system has been subjected to a safety and CE compliance check by AIB Vinçotte. You will receive the certificate upon delivery.

We have different brush sets so that you can change quickly and work more ergonomically during specific applications (such as flat work, welds, inner and outer corners, tubes).

Fill in the contact form below. We will process your request as quickly as possible.

We approach every project in a professional and pragmatic way. Discover our services: maintenance, revision & retrofitting, subcontracting, feasibility study and training.

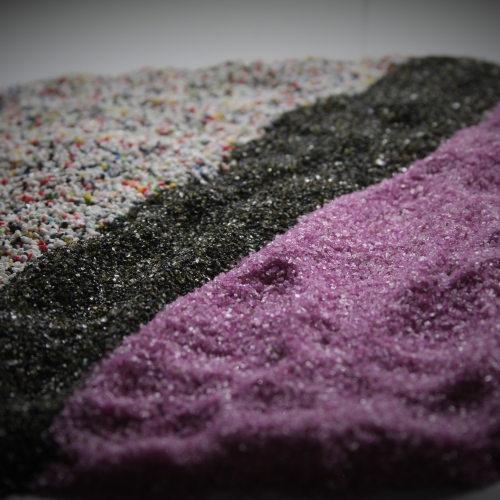

We can supply you with the appropriate abrasives for every application: glass beads, ceramic beads, aluminum oxide, plastic media, steel shot, steel grit, walnut shell, gommalite, stripalite, RGS metal cleaner and soda soft cleaner.

In our warehouse we have a large stock of spare parts, blasting media, cleaners and additives, tapes, personal protective equipment, measuring and verification devices, etc.