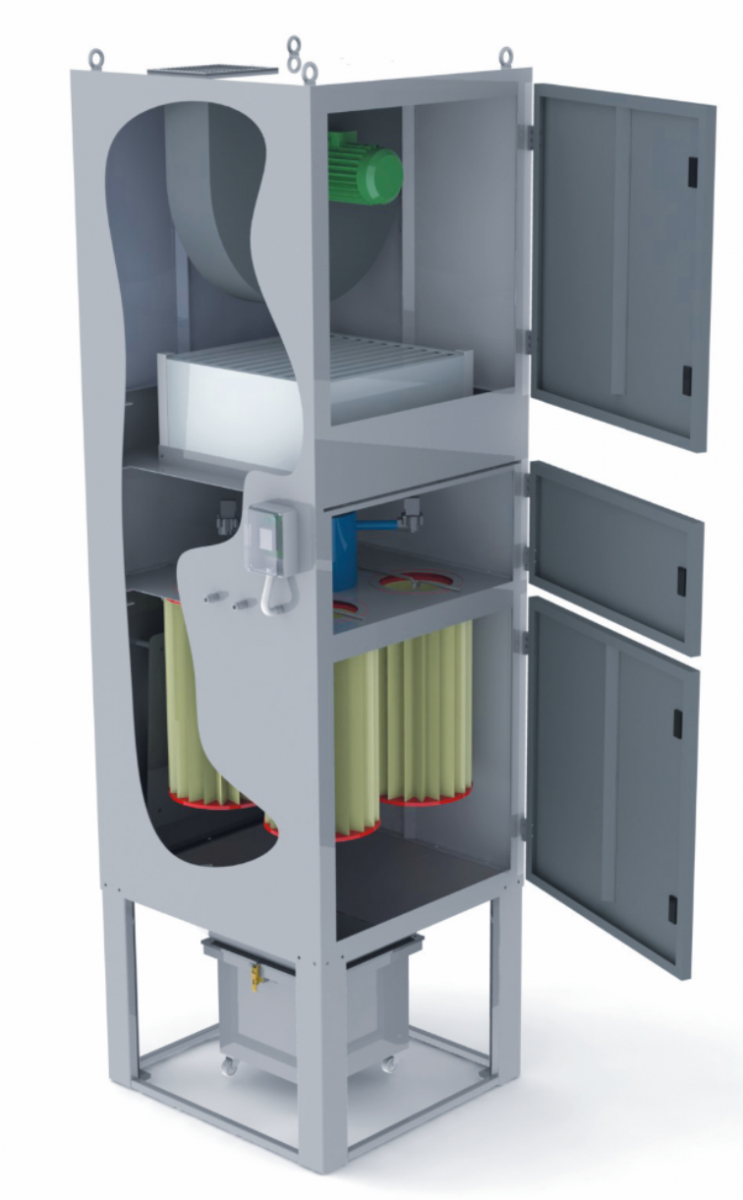

Access doors to the filter cartridges in the filter installation

An effective ventilation and filtration system is extremely important for your safety, health, working comfort and efficiency. Depending on your specific production situation, the air circulation is provided horizontally or vertically. The supply of fresh air and the extraction of the polluted air is evenly distributed over the entire cross-section of the blasting hall. This results in an even and good dust removal, without dead zones where dust lingers or settles. Moreover, thanks to this optimal ventilation principle, in combination with the labyrinth design of the frontal access doors, you have no loss of dust to your surrounding production space. This entire ventilation system complies with the regulations for working in confined spaces (code of good practice). Of course, the discharged air always conforms to the dust emission standards. If desired, the blasting hall can also be equipped with a heating element.

All installations are built in accordance with applicable standards and are available in various designs from small to large: PJDC0800, PJDC01500, PJDC03100, PJDC05300, PJDC08000, PJDC11000 and PJDC14000.

Our compact Pulsejet filter installations are equipped with anti-static filter cartridges. The filter cartridges are automatically sequentially cleaned via compressed air injections during the blasting process. This cleaning is controlled electronically via an adjustable microprocessor. The time between the compressed air injections can be set according to your needs. The dust is eventually collected in a mobile dust container at the bottom of the filter (other dust removal solutions are possible on request).

Fill in the contact form below. We will process your request as quickly as possible.

There are two types of abrasive transport systems: a pneumatic and an automatic system. The choice depends on the desired degree of automation, the intensity of use and the duration of the blasting work.

In addition to the blasting hall, we also provide all associated blasting equipment for the abrasive recuperation, such as the elevator, the cascade cleaner (the separator), the storage silo and the blast pots.

In our warehouse we have a large stock of spare parts, blasting media, cleaners and additives, tapes, personal protective equipment, measuring and verification devices, etc.