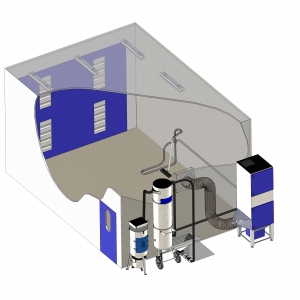

Pneumatic transport system

There are two types of abrasive transport systems: a pneumatic and an automatic scraper system. The choice depends on the desired degree of automation, the intensity of use and the average duration of the blasting works.

The abrasive is sucked in from the recovery funnel (in foundation) or from the abrasive gun (above ground). From here, the abrasive is transported to the cyclone unit where the dust and other impurities are separated from the abrasive. The reusable abrasive falls into the storage silo, the abrasive is sieved and flows back to the blasting vessel. This recovery process is done sequentially with every stop of the blasting process. The biggest advantage of this mechanical pneumatic recovery system is the limited wear and tear. This results in a low(er) operating cost (in comparison with the scraper system). If, on the other hand, you want continuous recovery, choose an automated system.

An additional recycling circuit, consisting of a vacuum cleaner, can easily be added to the basic equipment. With this you can also recover abrasive in hard-to-reach places (such as in recesses and inside corners of the blast hall or in the cavities of the pieces to be blasted) for a maximum recovery of the abrasive and a minimal loss.

The blasting agent falls through the floor gratings and ends up in the cascade cleaner via the container elevator. The abrasive is purified in this. The separated, fine dust particles are discharged to the dedusting installation and the purified abrasive to the storage silo on top of the blasting boiler. Coarse impurities are retained in the sieve.

The plug ’n play concept (the modular principle) gives you the opportunity to expand step by step. This way you can start with a partial automatic transport (1 or 2 scraper strips) and gradually expand to a fully automatic transport system (3 or more scraper strips) without any modification of the already installed equipment. The scraper strips can even be installed between rail tracks. Depending on your application, walkways made from sheet metal or heavy duty grids are sufficient. Heavy duty gratings carry a load capacity of 4 tons per wheel (200 x 200 mm) and heavy components can be placed directly on the gratings.

Fill in the contact form below. We will process your request as quickly as possible.

In addition to the blasting hall, we also provide all associated blasting equipment for the abrasive recuperation, such as the elevator, the cascade cleaner (the separator), the storage silo and the blast pots.

The supply of fresh air and the extraction of the polluted air is evenly distributed over the entire cross-section of the blasting hall. This results in an effective dust removal. Discover our PULSEJET dedusting installations.

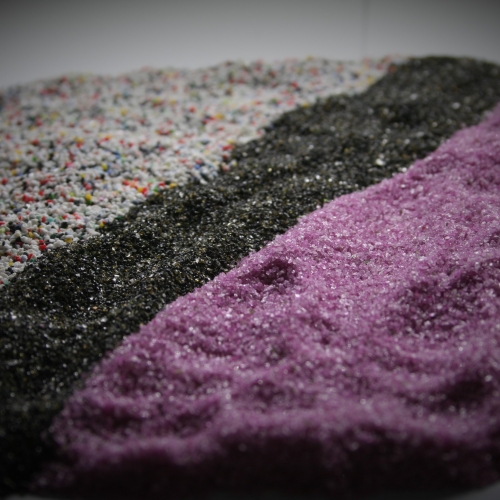

We can supply you with the appropriate abrasives for every application: glass beads, ceramic beads, aluminum oxide, plastic media, steel shot, steel grit, walnut shell, gommalite, stripalite, RGS metal cleaner and soda soft cleaner.