The PRO 0806/2 is adjustable in height for maximum working comfort and minimum total body burden. An ergonomic design does not only benefit your job satisfaction but also improves the quality and efficiency of your blasting work.

The PRO-impact line consists of our dry blasting cabinets. Depending on your application you choose:

The blasting cabinets are available in various standard dimensions: PRO 0806/2, PRO 1208, PRO 1510, PRO 2010 and PRO 2510.

Get acquainted with our PRO 0806/2. The ergonomic turntable, the adjustable working height, the maximum illumination (high light output with limited energy consumption) and the extra large viewing window at an adjusted angle considerably improve the operator's working comfort.

The PRO 0806/2 is adjustable in height for maximum working comfort and minimum total body burden. An ergonomic design does not only benefit your job satisfaction but also improves the quality and efficiency of your blasting work.

You enjoy maximum lighting and visibility thanks to the size of the viewing window, the specific positioning and the LED lighting kit.

You can fix the blasting gun for the meticulous handling of small parts.

PRO 1510 with lateral door and external loading table on walker

Left: PRO 1510 with frontal (space saving) door and side openings with loose blasting gloves. Right: PRO 1510 with larger side openings and fixed blasting gloves.

Detail a PRO 1510 side opening

PRO 2510 for the treatment of larger parts

PRO 2510 inside

PRO 2510 with external loading table

The projection system depends on the application, frequency of use, desired speed and budget.

Choose a vacuum system when you occasionally blast and speed is secondary. The blasting abrasive is sucked in from the reservoir and accelerated at the height of the blasting gun by means of compressed air.

A pressure system radiates up to three times faster and more powerful. Choose a pressure system when you use the installation intensively and want a high return. The abrasive is pushed to the nozzle under pressure. This stream is consistent and powerful. Thanks to the dosing device you can control the quantity of abrasive .

Filtration and recuperation system based on the pressure principle

Filter cartridges made from antistatic filter material are automatically and sequentially cleaned by means of compressed air impulses

Filtration and recuperation system based on the vacuum principle whereby 2 different types of abrasives are collected

Fill in the contact form below. We will process your request as quickly as possible.

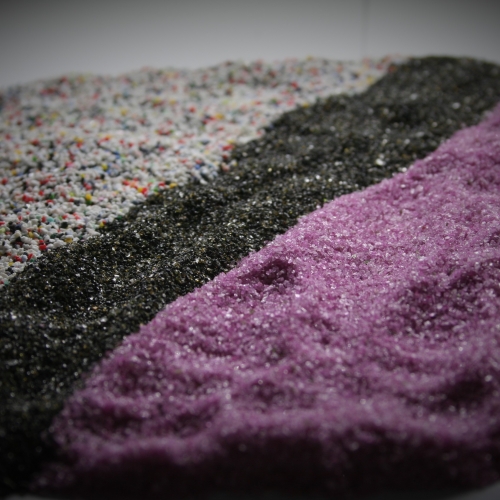

We can supply you with the appropriate abrasives for every application: glass beads, ceramic beads, aluminum oxide, plastic media, steel shot, steel grit, walnut shell, gommalite, stripalite, RGS metal cleaner and soda soft cleaner.

In our warehouse we have a large stock of spare parts, blasting media, cleaners and additives, tapes, personal protective equipment, measuring and verification devices, etc.

We approach every project in a professional and pragmatic way. Discover our services: maintenance, revision & retrofitting, subcontracting, feasibility study and training.